3c Electronics

The 3C industry is an industry that produces electronic communication products such as computers, mobile phones, watches, cameras and related accessories. Since electronic products have only started to develop at a high speed in the past ten years, electronic products are still developing in a mature direction, and the equipment produced by them is also changing due to the continuous changes of electronic products. Therefore, there are few standard and general-purpose equipment, and even some relatively mature standard machines will still be optimized or even redesigned according to changes in customer product process requirements.

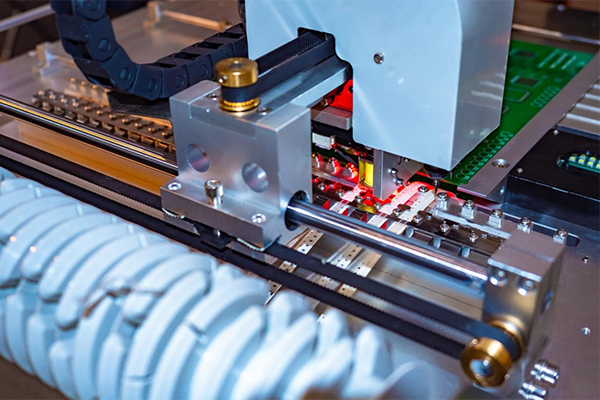

Inspection Conveyor ☞

The inspection conveyor is mostly used for the connection between SMT and AI production lines, and can also be used for slow movement between PCBs, detection, testing or manual insertion of electronic components. Rite Technology provides a series of multi-axis products for docking table control requirements to ensure the synchronization of transportation and perfectly adapt to docking table applications.

Chip Mounter ☞

Chip Mounter, also known as "Surface Mount System", is a device that is configured behind a dispenser or a screen printing machine to accurately place surface mount components on PCB pads by moving the mounting head. It is the equipment used to realize high-speed and high-precision placement of components, and it is the most critical and complex equipment in the entire SMT production.

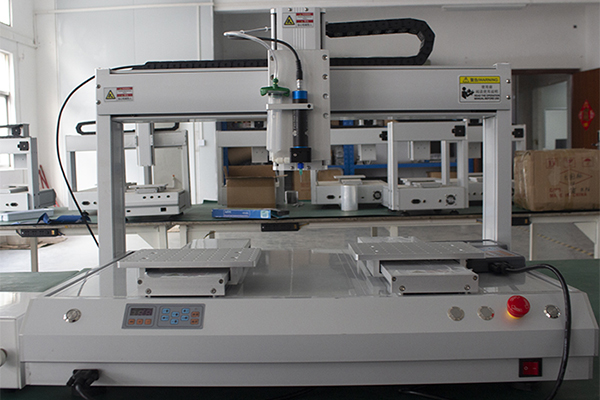

Dispenser ☞

Glue dispensing machine, also known as glue applicator, glue dropping machine, glue machine, glue pouring machine, etc., is an automatic machine that controls the fluid and applies the fluid to the surface of the product or inside the product. Rtelligent Technology provides a variety of industrial control products to help customers achieve three-dimensional and four-dimensional path dispensing, precise positioning, precise glue control, no wire drawing, no glue leakage, and no glue dripping.

Screw Machine ☞

The automatic locking screw machine is a kind of automatic locking screw machine that realizes screw feeding, hole alignment and tightening through the cooperative work of motors, position sensors and other components, and at the same time realizes the automation of screw locking results detection based on torque testers, position sensors and other equipment device. Ruite Technology has specially developed and customized a low-voltage servo screw machine solution for customers to choose, which has less interference during operation, a lower machine failure rate, and is suitable for high-speed movement, thereby increasing product output.