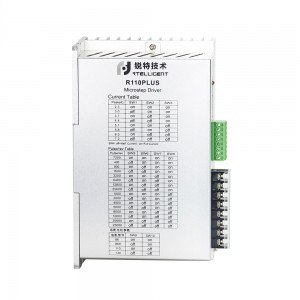

Digital Stepper Driver R110PLUS

Product Introduction

Connection

Features

• Working Voltage :18~80VAC or 24~100VDC

• Communication: USB to COM

• Maximum Phase Current output: 7.2A/Phase (Sinusoidal Peak)

• PUL+DIR, CW+CCW pulse mode optional

• Phase loss alarm function

• Half-current function

• Digital IO port:

3 photoelectric isolation digital signal input, high level can directly receive 24V DC level;

1 photoelectric isolated digital signal output, maximum withstand voltage 30V, maximum input or pull-out current 50mA.

• 8 gears can be customized by users

• 16 gears can be subdivided by user-defined subdivision, supporting arbitrary resolution in the range of 200-65535

• IO control mode, support 16 speed customization

• Programmable input port and output port

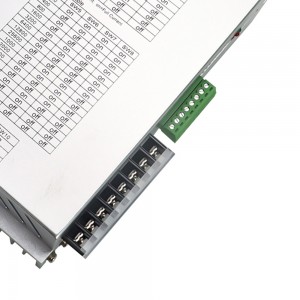

Current Setting

|

Sine peak A |

SW1 |

SW2 |

SW3 |

Remarks |

|

2.3 |

on |

on |

on |

Users can set up 8 level currents through debugging software. |

|

3.0 |

off |

on |

on |

|

|

3.7 |

on |

off |

on |

|

|

4.4 |

off |

off |

on |

|

|

5.1 |

on |

on |

off |

|

|

5.8 |

off |

on |

off |

|

|

6.5 |

on |

off |

off |

|

|

7.2 |

off |

off |

off |

Micro-stepping Setting

|

Steps / revolution |

SW5 |

SW6 |

SW7 |

SW8 |

Remarks |

|

7200 |

on |

on |

on |

on |

Users can set up 16 level subdivision through debugging software . |

|

400 |

off |

on |

on |

on |

|

|

800 |

on |

off |

on |

on |

|

|

1600 |

off |

off |

on |

on |

|

|

3200 |

on |

on |

off |

on |

|

|

6400 |

off |

on |

off |

on |

|

|

12800 |

on |

off |

off |

on |

|

|

25600 |

off |

off |

off |

on |

|

|

1000 |

on |

on |

on |

off |

|

|

2000 |

off |

on |

on |

off |

|

|

4000 |

on |

off |

on |

off |

|

|

5000 |

off |

off |

on |

off |

|

|

8000 |

on |

on |

off |

off |

|

|

10000 |

off |

on |

off |

off |

|

|

20000 |

on |

off |

off |

off |

|

|

25000 |

off |

off |

off |

off |

FAQ

Q1. What is a digital stepper driver?

A: A digital stepper driver is an electronic device used to control and operate stepper motors. It receives digital signals from the controller and converts them into precise electrical pulses that drive stepper motors. Digital stepper drives offer greater accuracy and control than traditional analog drives.

Q2. How does a digital stepper driver work?

A: Digital stepper drives operate by receiving step and direction signals from a controller, such as a microcontroller or PLC. It converts these signals into electrical pulses, which are then sent to the stepper motor in a specific sequence. The driver controls the current flow to each winding phase of the motor, allowing precise control of the motor's motion.

Q3. What are the advantages of using digital stepper drivers?

A: There are several advantages to using digital stepper drivers. First, it provides precise control of stepper motor movement, allowing precise positioning of the motor shaft. Second, digital drives often have microstepping capabilities, which allow the motor to run smoother and quieter. Additionally, these drivers can handle higher current levels, making them suitable for more demanding applications.

Q4. Can digital stepper drivers be used with any stepper motor?

A: Digital stepper drivers are compatible with a variety of stepper motor types, including bipolar and unipolar motors. However, it is critical to ensure compatibility between the voltage and current ratings of the drive and motor. Additionally, the driver should be able to support the step and direction signals required by the controller.

Q5. How do I choose the right digital stepper driver for my application?

A: To choose the right digital stepper driver, consider factors such as the stepper motor's specifications, desired level of accuracy, and current requirements. Additionally, if smooth motor operation is a priority, ensure compatibility with the controller and evaluate the drive's microstepping capabilities. It is also recommended to consult the manufacturer's data sheet or seek expert advice to make an informed decision.

-

Rtelligent R110Plus User Manual

Rtelligent R110Plus User Manual