-

Small PLC RX8U Series

Based on years of experience in the field of industrial automation control systems, programmable logic controller manufacturer. Rtelligent has launched a series of PLC motion control products, including small, medium and larged sized PLCs.

The RX series is the latest pulse PLC developed by Rtelligent. The product comes with 16 switching input points and 16 switching output points, optional transistor output type or relay output type. Host computer programming software compatible with GX Developer8.86/GX Works2, instruction specifications compatible with Mitsubishi FX3U series, faster running. Users can connect programming through the Type-C interface that comes with the product.

-

AC Servo Drive with EtherCAT RS400E/RS750E/RS1000E/RS2000E

RS series AC servo is a general servo product line developed by Rtelligent, covering the motor power range of 0.05~3.8kw. RS series supports ModBus communication and internal PLC function, and RSE series supports EtherCAT communication. RS series servo drive has a good hardware and software platform to ensure that it can be very suitable for fast and accurate position, speed, torque control applications.

• Better hardware design and higher reliability

• Matching motor power below 3.8kW

• Complies with CiA402 specifications

• Support CSP/CSW/CST/HM/PP/PV control mode

• The minimum synchronization period in CSP mode: 200bus

-

Cost-Effective AC Servo Drive RS400CR / RS400CS/ RS750CR /RS750CS

RS series AC servo is a general servo product line developed by Rtelligent, covering the motor power range of 0.05 ~ 3.8kw. RS series supports ModBus communication and internal PLC function, and RSE series supports EtherCAT communication. RS series servo drive has a good hardware and software platform to ensure that it can be very suitable for fast and accurate position, speed, torque control applications.

• High stability, Easy and convenient debugging

• Type-c: Standard USB, Type-C Debug interface

• RS-485: with standard USB communication interface

• New front interface to optimize wiring layout

• 20Pin press-type control signal terminal without soldering wire, easy and fast operation

-

High-Performance AC Servo Dve R5L028/ R5L042/R5L130

The fifth generation high-performance servo R5 series is based on the powerful R-AI algorithm and a new hardware solution. With Rtelligent rich experience in the development and application of servo for many years, the servo system with high performance, easy application and low cost has been created. Products in 3C, lithium, photovoltaic, logistics, semiconductor, medical, laser and other high-end automation equipment industry has a wide range of applications.

· Power range 0.5kw~2.3kw

· High dynamic response

· One-key self-tuning

· Rich IO interface

· STO security features

· Easy panel operation

-

Fieldbus Closed Loop Stepper Drive ECT42/ ECT60/ECT86

The EtherCAT fieldbus stepper drive is based on the CoE standard framework and complies with the CiA402

standard. The data transmission rate is up to 100Mb/s, and supports various network topologies.

ECT42 matches closed loop stepper motors below 42mm.

ECT60 matches closed loop stepper motors below 60mm.

ECT86 matches closed loop stepper motors below 86mm.

• ontrol mode: PP, PV, CSP, HM, etc

• Power supply voltage: 18-80VDC (ECT60), 24-100VDC/18-80VAC (ECT86)

• Input and output: 4-channel 24V common anode input; 2-channel optocoupler isolated outputs

• Typical applications: assembly lines, lithium battery equipment, solar equipment, 3C electronic equipment, etc

-

Fieldbus Open Loop Stepper Drive ECR42 / ECR60/ ECR86

The EtherCAT fieldbus stepper drive is based on the CoE standard framework and complies with the CiA402 standard. The data transmission rate is up to 100Mb/s, and supports various network topologies.

ECR42 matches open loop stepper motors below 42mm.

ECR60 matches open loop stepper motors below 60mm.

ECR86 matches open loop stepper motors below 86mm.

• Control mode: PP, PV, CSP, HM, etc

• Power supply voltage: 18-80VDC (ECR60), 24-100VDC/18-80VAC (ECR86)

• Input and output: 2-channel differential inputs/4-channel 24V common anode inputs; 2-channel optocoupler isolated outputs

• Typical applications: assembly lines, lithium battery equipment, solar equipment, 3C electronic equipment, etc

-

New generation 2 Phase Closed Loop Stepper Drive T60S /T86S

The T-S series is an upgraded version of the open-loop stepper driver launched by Rtelligent, and the product design idea is derived from the our experience accumulation

in the field of stepper drive over the years. By using a new architecture and algorithm, the new generation of stepper driver effectively reduces the low-speed resonance amplitude of the motor, has a stronger anti-interference ability, while supporting non-inductive rotation detection, phase alarm and other functions, support a variety of pulse command forms, multiple dip Settings.

-

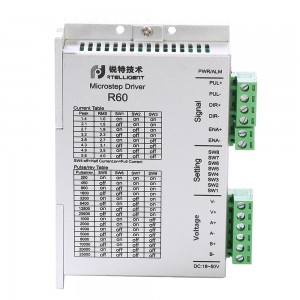

Classic 2 Phase Open Loop Stepper Drive R60

Based on the new 32-bit DSP platform and adopting the micro-stepping technology and PID current control algorithm

design, Rtelligent R series stepper drive surpasses the performance of common analog stepper drive comprehensively.

The R60 digital 2-phase stepper drive is based on 32-bit DSP platform,with built-in micro-stepping technology & auto tuning of parameters. The drive features low noise, low vibration, low heating and high-speed high torque output.

It is used to drive two-phase stepper motors base below 60mm

• Pulse mode: PUL&DIR

• Signal level: 3.3~24V compatible; series resistance not required for the application of PLC.

• Power voltage: 18-50V DC supply; 24 or 36V recommended.

• Typical applications: engraving machine, labeling machine, cutting machine, plotter, laser, automatic assembly equipment, etc.

-

2 Phase Open Loop Stepper Drive R42

Based on the new 32-bit DSP platform and adopting the micro-stepping technology and PID current control algorithm design, Rtelligent R series stepper drive surpasses the performance of common analog stepper drive comprehensively. The R42 digital 2-phase stepper drive is based on 32-bit DSP platform,with built-in micro-stepping technology& auto tuning of parameters. The drive features low noise, low vibration and low heating. • Pulse mode: PUL&DIR • Signal level: 3.3~24V compatible; series resistance not required for the application of PLC. • Power voltage: 18-48V DC supply; 24 or 36V recommended. • Typical applications: marking machine, soldering machine, laser, 3D printing, visual localization, automatic assembly equipment, • etc.

-

IO Speed Control Switch Stepper Drive R60-IO

IO series switch stepper drive, with built-in S-type acceleration and deceleration pulse train, only need switch to trigger

motor start and stop. Compared with speed regulating motor, IO series of switching stepper drive has the characteristics of stable start and stop, uniform speed, which can simplify the electrical design of engineers.

• ontrol mode: IN1.IN2

• Speed setting: DIP SW5-SW8

• Signal level: 3.3-24V Compatiable

• Typical appications: conveying equipment, inspection converyor, PCB loader

-

3 Phase Open Loop Stepper Drive 3R130

The 3R130 digital 3-phase stepper drive is based on patented three-phase demodulation algorithm, with built-in micro

stepping technology, featuring low speed resonance, small torque ripple. It can fully play the performance of three-phase

stepper motors.

3R130 is used to drive three-phase stepper motors base below 130mm.

• Pulse mode: PUL & DIR

• Signal level: 3.3~24V compatible; series resistance not necessary for the application of PLC.

• Power voltage: 110~230V AC;

• Typical applications: engraving machine, cutting machine, screen printing equipment, CNC machine, automatic assembly

• equipment, etc.

-

3 Phase Open Loop Stepper Drive 3R60

The 3R60 digital 3-phase stepper drive is based on patented three-phase demodulation algorithm, with built-in micro

stepping technology, featuring low speed resonance, small torque ripple. It can fully play the performance of three-phase

stepper motor.

3R60 is used to drive three-phase stepper motors base below 60mm.

• Pulse mode: PUL & DIR

• Signal level: 3.3~24V compatible; Series resistance not required for the application of PLC.

• Power voltage: 18-50V DC; 36 or 48V recommended.

• Typical applications: dispenser, soldering machine, engraving machine, laser cutting machine,3D printer, etc.