-

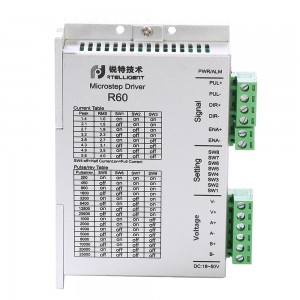

Classic 2 Phase Open Loop Stepper Drive R60

Based on the new 32-bit DSP platform and adopting the micro-stepping technology and PID current control algorithm design, Rtelligent R series stepper drive surpasses the performance of common analog stepper drive comprehensively.

The R60 digital 2-phase stepper drive is based on 32-bit DSP platform,with built-in micro-stepping technology & auto tuning of parameters. The drive features low noise, low vibration, low heating and high-speed high torque output.

It is used to drive two-phase stepper motors base below 60mm

• Pulse mode: PUL&DIR

• Signal level: 3.3~24V compatible; series resistance not required for the application of PLC.

• Power voltage: 18-50V DC supply; 24 or 36V recommended.

• Typical applications: engraving machine, labeling machine, cutting machine, plotter, laser, automatic assembly equipment, etc.

-

Fieldbus Open loop Stepper Drive ECR60X2A

The EtherCAT fieldbus open loop stepper drive ECR60X2A is based on the CoE standard framework and complies with the CiA402 standard. The data transmission rate is up to 100Mb/s, and supports various network topologies.

ECR60X2A matches open loop stepper motors below 60mm.

• Control modes: PP, PV, CSP, CSV, HM, etc

• Power supply voltage: 18-80V DC

• Input and output: 8-channel 24V common positive input; 4-channel optocoupler isolation outputs

• Typical applications: assembly lines, lithium battery equipment, solar equipment, 3C electronic equipment, etc

-

Fieldbus Closed Loop Stepper Drive ECT86

The EtherCAT fieldbus stepper drive is based on the CoE standard framework and complies with the CiA402

standard. The data transmission rate is up to 100Mb/s, and supports various network topologies.

ECT42 matches closed loop stepper motors below 42mm.

ECT60 matches closed loop stepper motors below 60mm.

ECT86 matches closed loop stepper motors below 86mm.

• ontrol mode: PP, PV, CSP, HM, etc

• Power supply voltage: 18-80VDC (ECT60), 24-100VDC/18-80VAC (ECT86)

• Input and output: 4-channel 24V common anode input; 2-channel optocoupler isolated outputs

• Typical applications: assembly lines, lithium battery equipment, solar equipment, 3C electronic equipment, etc

-

Fieldbus Closed Loop Stepper Drive ECT60

The EtherCAT fieldbus stepper drive is based on the CoE standard framework and complies with the CiA402

standard. The data transmission rate is up to 100Mb/s, and supports various network topologies.

ECT42 matches closed loop stepper motors below 42mm.

ECT60 matches closed loop stepper motors below 60mm.

ECT86 matches closed loop stepper motors below 86mm.

• ontrol mode: PP, PV, CSP, HM, etc

• Power supply voltage: 18-80VDC (ECT60), 24-100VDC/18-80VAC (ECT86)

• Input and output: 4-channel 24V common anode input; 2-channel optocoupler isolated outputs

• Typical applications: assembly lines, lithium battery equipment, solar equipment, 3C electronic equipment, etc

-

Fieldbus Closed Loop Stepper Drive ECT42

The EtherCAT fieldbus stepper drive is based on the CoE standard framework and complies with the CiA402

standard. The data transmission rate is up to 100Mb/s, and supports various network topologies.

ECT42 matches closed loop stepper motors below 42mm.

ECT60 matches closed loop stepper motors below 60mm.

ECT86 matches closed loop stepper motors below 86mm.

• ontrol mode: PP, PV, CSP, HM, etc

• Power supply voltage: 18-80VDC (ECT60), 24-100VDC/18-80VAC (ECT86)

• Input and output: 4-channel 24V common anode input; 2-channel optocoupler isolated outputs

• Typical applications: assembly lines, lithium battery equipment, solar equipment, 3C electronic equipment, etc

-

Fieldbus Open Loop Stepper Drive ECR86

The EtherCAT fieldbus stepper drive is based on the CoE standard framework and complies with the CiA402 standard. The data transmission rate is up to 100Mb/s, and supports various network topologies.

ECR42 matches open loop stepper motors below 42mm.

ECR60 matches open loop stepper motors below 60mm.

ECR86 matches open loop stepper motors below 86mm.

• Control mode: PP, PV, CSP, HM, etc

• Power supply voltage: 18-80VDC (ECR60), 24-100VDC/18-80VAC (ECR86)

• Input and output: 2-channel differential inputs/4-channel 24V common anode inputs; 2-channel optocoupler isolated outputs

• Typical applications: assembly lines, lithium battery equipment, solar equipment, 3C electronic equipment, etc

-

Fieldbus Open Loop Stepper Drive ECR60

The EtherCAT fieldbus stepper drive is based on the CoE standard framework and complies with the CiA402 standard. The data transmission rate is up to 100Mb/s, and supports various network topologies.

ECR42 matches open loop stepper motors below 42mm.

ECR60 matches open loop stepper motors below 60mm.

ECR86 matches open loop stepper motors below 86mm.

• Control mode: PP, PV, CSP, HM, etc

• Power supply voltage: 18-80VDC (ECR60), 24-100VDC/18-80VAC (ECR86)

• Input and output: 2-channel differential inputs/4-channel 24V common anode inputs; 2-channel optocoupler isolated outputs

• Typical applications: assembly lines, lithium battery equipment, solar equipment, 3C electronic equipment, etc

-

Fieldbus Open Loop Stepper Drive ECR42

The EtherCAT fieldbus stepper drive is based on the CoE standard framework and complies with the CiA402 standard. The data transmission rate is up to 100Mb/s, and supports various network topologies.

ECR42 matches open loop stepper motors below 42mm.

ECR60 matches open loop stepper motors below 60mm.

ECR86 matches open loop stepper motors below 86mm.

• Control mode: PP, PV, CSP, HM, etc

• Power supply voltage: 18-80VDC (ECR60), 24-100VDC/18-80VAC (ECR86)

• Input and output: 2-channel differential inputs/4-channel 24V common anode inputs; 2-channel optocoupler isolated outputs

• Typical applications: assembly lines, lithium battery equipment, solar equipment, 3C electronic equipment, etc

-

New Dual-axis field bus type closed loop stepper drive EST60X2

Elevate your automation performance with the Rtelligent EST60X2, a revolutionary dual-axis bus stepper drive engineered for seamless integration and peak efficiency. Designed for motors up to 60mm, the EST60X2

supports CoE (CANopen over EtherCAT) and EtherNet/IP, complies with the CiA402 standard, and is compatible with various network topologies such as linear and ring. This new product delivers exceptional control and versatility in a compact form factor.

●Support CSP, CSV, PP, PV, and Homing modes;

● Minimum synchronization period: 100 μs;

● Brake port: Direct connection to brake;

● Five-digit digital tube display makes it more convenient to monitor and modify parameters.

●Control methods: Open-loop control, closed-loop control;

● Supported motor types: two-phase, three-phase;

The Rtelligent EST60X2: Where Power, Precision, and Protocol Flexibility Converge. Optimize Your Motion Control Today. Achieve ultra-smooth and synchronized motion with a remarkably low minimum sync cycle of just 100 microseconds.

-

New generation of fieldbus closed loop stepper driver EST60

Rtelligent EST Series Bus Stepper Driver – A high-performance motion control solution designed for industrial automation. This advanced driver integrates EtherCAT, Modbus TCP, and EtherNet/IP multi-protocol support, ensuring seamless compatibility with diverse industrial networks. Built on the CoE (CANopen over EtherCAT) standard framework and fully compliant with CiA402 specifications, it delivers precise and reliable motor control. The EST Series supports flexible linear, ring, and other network topologies, enabling efficient system integration and scalability for complex applications.

Support CSP, CSV, PP, PV, Homing modes;

● Minimum synchronization cycle: 100us;

● Brake port: Direct brake connection

● User-friendly 4-digit digital display enables real-time monitoring and quick parameter modification

● Control method: open loop control, closed loop control;

● Support motor type: two-phase, three-phase;

● EST60 matches stepper motors below 60mm

-

Advanced Fieldbus Digital Stepper Drive NT86

485 fieldbus stepper drive NT60 is based on RS-485 network to run Modbus RTU protocol. The intelligent motion control

function is integrated, and with external IO control, it can complete functions such as fixed position/fixed speed/multi

position/auto-homing.

NT86 matches open loop or closed loop stepper motors below 86mm.

• Control mode: fixed length/fixed speed/homing/multi-speed/multi-position/potentiometer speed regulation

• Debugging software: RTConfigurator (multiplexed RS485 interface)

• Power voltage: 18-110VDC, 18-80VAC

• Typical applications: single axis electric cylinder, assembly line, multi-axis positioning platform, etc

-

Closed Loop Fieldbus Stepper Drive NT60

485 fieldbus stepper drive NT60 is based on RS-485 network to run Modbus RTU protocol. The intelligent motion control

function is integrated, and with external IO control, it can complete functions such as fixed position/fixed speed/multi

position/auto-homing

NT60 matches open loop or closed loop stepper motors below 60mm

• Control mode: fixed length/fixed speed/homing/multi-speed/multi-position

• Debugging software: RTConfigurator (multiplexed RS485 interface)

• Power voltage: 24-50V DC

• Typical applications: single axis electric cylinder, assembly line, connection table, multi-axis positioning platform, etc